Highly practical solutions for any vacuum tubes and processes.

X-ray, gamma, betatron, microwave, neutron tubes, systems, applications and more.

Elegantly and simply.

Simplicity

Having started my career in vacuum tubes for space satellites for extreme reliability and life; fundamental core solutions are regularly straightforward.

Email or call for free information on your project and the value we can provide, project timeline, and cost.

All correspondence is

confidential and secure.

Experience

With over 50 years of passionate, hands-on, practical experience, producing top results & working with top firms globally and by producing solutions for processes and developments within the vacuum tube environment/ industry.

I have always loved what I do!

World-Class Excellence

Being aware of every company globally (that makes X-ray sources, (a personal hobby), and knowing their strengths, flaws, and history; is the ONLY way to be able to state and evaluate with authority that something is World-Class. All solutions and designs are at and usually exceed this level.

About

Simplis is passionate about simplicity

The best answers are simple and straightforward. The best designs, elegant; and fusing the two is what Simplis does best. It is always the simple that produces the marvelous. -Amelia Edith Huddleston Barr “If you can't explain it simply, you don't understand it well enough.” Einstein “Simplicity is the ultimate sophistication.” Leonardo DaVinci “Everything should be made as simple as possible, ...” Einstein

Who I am

An extremely practical, hands on, highly motivated individual, that has always been passionate about high voltage, vacuum and all tube technology and has consistently been the top performer. I have had presidents, CEO’s & VP’s track me down and come to my house to personally ask me to work with them after they realize how far ahead it put their companies.

Miniature tubes, 1 inch, (25mm), dia. and sizes through and down to 1/8 inch, (3mm), dia. Portable, handheld, military and up to a 6-foot cube.

Energies from a stable 1.6eV to 10MeV.

I have literally been the backup for the entire workforce for companies, quickly solved issues, invented, modeled, drawn, and produced industry’s top products and tracked down to compare the world’s best in any subject, designed, R&D, and produced $1.5b in sales in 1 product line for 1 company where the quality was so good that the business team never even heard of arcing as an issue. In fact, one manager asked me years later if our source was even capable of arcing.

I provide high tech consultations on x-ray, gamma, betatron, microwave, neutron, accelerators, (circular and linear), TWT and BWO sources and systems as well as any VEDs, (Vacuum Electron Devices)

Private Pilot license

Our Mission

Dedicated to elevate global excellence in sources with the intent of bettering life globally.

Helping business, security, individuals, and teams grow, become successful, impowered, and accomplish what they didn’t even believe was possible.

Even with seasoned scientists, engineers, or managers, I have had them corner me and say that they didn’t even know “that” was possible.

It is a real treat to see others smiling based on their success.

Creating/ building winning teams, and creating or expanding businesses with new product lines.

Nothing beats success!

What We Do

- Failure Analysis

- Design

- Electron optics

- Material specification

- Material sourcing

- Machining

- Chemical Processing

- Coating Processes, Sputtering, CVD, PVD, IBAD, e-beam, laser, cathodic-arc plating ...

- Brazing, Vac, RF Induct. Protective atmos, pushers, belt, camelbacks...

- Emitters, direct, indirect, secondary

- Welding, TIG, MIG, Cold, Ion, spot, ....

- ultra-high vacuums 10-14 torr

- accurate low vacuums

- Glass blowing and molding

- insulators, Borosilicate and Aluminosilicate glass

- Ceramics, metal seals

- HALT/ HAST

- High Voltage stable from 500VDC to 10kVDC, to 50kV to 300kV, and 10MeV

- Epoxy casting

- Cables, High Volt connectors

- Stability a speciality

- Spot stability, uniformity

- And much more

Examples of excellence, speed, and a few learnings

01.

Speed, Emitters

My 1st day at a new company, I was invited to a production meeting where they were talking about “the filament problem” which had plagued the quality of the source for the last 10 years! Customers regularly demanded and received huge discounts due to unreliable quality & performance and commonly used 3 separate vendors for AOS, (Assurance of Supply.)

After hearing this, I recommended that I immediately fly to the vendor and straighten things out. Everyone told me how it wouldn’t/ couldn’t work, it had been tried before by experts, and the vendor didn’t want anyone coming to “steal his process.”

After a few days at the vendors, we had identified the critical few things and within the week the yield had gone up 70%+ and things simply continued to get better.

The vendor was very happy, both companies made more profit, and both had a strong AOS.

Sales for the X-ray device were much smoother, returns dropped and discounts were no longer needed.

Afterwards a few others claimed they could have done the same thing but after they lived with it for 10-years, it is not always about technically knowing, (which they truly did not), but knowing how to effect changes in a positive manner where everyone wins.

Accomplished: set the stage for solution in first day/ week of employment.

02.

Excellence, High Voltage PS

Our customer wanted to improve performance and wanted capabilities in a handheld system that even 99% of the highest quality lab systems couldn’t do. When I took the task on, I identified the stakeholders in all our companies; customer, us, and our component vendor and sent e-mails to insure we were all on the same page.

After I quickly identified the errant component in our vendors power supply, our vendor started a process to weed-out the “bad ones”. It was elaborate, time consuming, and not as effective as it should have been. While that was going on, I started communicating with the manufacturer/ vendor of the errant components who said that they had never been able to achieve the specs we needed. After reviewing their process and seeing that it was standard, I went to their vendor for the raw material. I explained what was happening and the specs and my theory of the molecular-level interactions and what was happening. They immediately agreed and explained the changes in the process required to fix it. The entire process took 3 months. All stakeholders were extremely happy, (I would say even “delighted”), and the product now commands a best-in-market premium price with the product being a source of pride for the entire supply chain.

This solution was a “Fortune-50″/ World-Class action and timing.

03.

DHS US -Dept of HomeLand Security-

I was hired at another company to solve a product life issue, as my boss, (the VP of another international Security company), was being called to testify every month before congress as to why the product was dying prematurely.

As it was a complicated system I had to clear ITAR for me before traveling around the world to vendors and helped improve transformers, mainly for HV standoff, vacuum tubes, analyzed vacuum, materials, processes, glass coatings, tests, and then I brought in the correct equipment for measuring what the team didn’t understand at first. I identified and solved the problem, developed critical feedback channels and connections and brought the entire team’s knowledge up.

I was there about a year and felt that due to the field support, management, purchasing, production, and the entire divisions support, I had the final document, (of success), give credit to the entire division. I may have been the scalpel and one that identified specific solutions but it was everyone that kept the customers going in the bad times and made it possible for me to do my work.

The entire division was rewarded after the success.

1 month after I was hired, my boss no longer needed to go before congress.

I left that company as even though they used X-ray sources, they were not interested in making them or in advancing the product.

04.

Making it possible

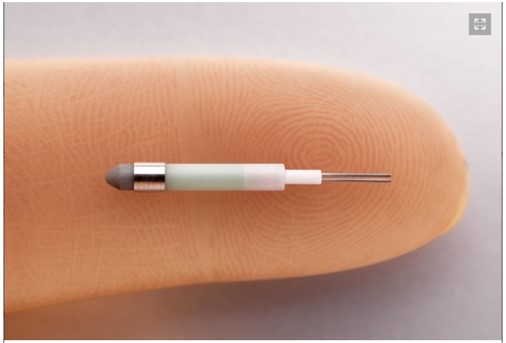

I was hired for 1 week to solve a problem with a tiny tube, (size of a grain of rice), that at a peak, (had 23 PhDs on staff with at least 6 working for 12 years, making 100’s a week), with a reported high yield of 8%, of which none actually met full spec. The second day there I knew 100% what was wrong and how to solve it. They were using GMP -good manufacturing practices- as this was medical- so I could not make any immediate changes. They had also requested a full written report so after I had come in early to go through every process I spent my time writing the report and confirming my analysis.

Within the month, their yield was at greater than 85% and continuing to climb and all the tubes exceeded spec.

Surprisingly, the CEO told me I could show anyone anything about the tube and any part of it, offered that I could call and ask for a tube to show anyone anytime and it would be immediately sent to me. The ONLY stipulation was that I could not use their company name. I said it would be easy to figure out the company but the CEO was perfectly content with what he had said.

05.

DHS UK

The CTO of another global security company asked me to fly to England to look at a project that had stagnated for over 4 years without any hope of product, and the company CEO wanted results.

The PhD’s running the project were excellent as were the board members that were backing them up. The board consisted of College professors, authors on specific subjects, manufacturing leaders, drafters, and engineers.

After the morning touring the manufacturing and reviewing drawings and vendors, we had lunch with everyone there. I reported the main crippling issues and how to solve them and within 3 to 6 months the team was producing working product. The CEO was extremely pleased.

I flew home the following day so really it took 1 lunch to solve what very talented and experienced people struggled with for >3 years. Besides that, the book that the team was using as a “bible”, I tracked the author down as a retired professor and discussed some of the books findings and encouraged him to write a 3rd ed to bring all the disparate ideas to a narrow focus for everyone’s benefit, which he did about 6 years later.

06.

Reduced costs

We doubled business output while holding expenses below original targets.

As the production manager over 5 separate businesses and >200 people, for a Fortune 10 company, I worked with the site engineering manager for all businesses. He was explaining how shipments were in danger because of a laser range-finder from China not performing to spec. Problems were the language barrier and the fact that the lasers were permanently sealed. Engineering had been trying for > 3 months, dealing with dipping quality and needing to sort for useable ones.

I asked for a bad laser, put it in a vice in front of the engineering manager, crushed it open, took a picture, gave it to him and we immediately solved the problem and could place arrows on the picture to show the actual problems and how to solve them. He was thrilled, the vendor was happy, and our $30M/ mo. product line kept moving.

I designed and manufactured the heart of the system which brought in >$1.4b USD in revenue and the X-ray sources have operated for >>15 years.

07.

Speed

A new division manager, (DM), was hired and we reviewed my project list. One stood out as being months overdue and the question was why. The project wanted ceramic and my ceramic vendor was not having any luck. The DM asked if I could make it in glass. That was Friday, by the very next Monday I handed the new DM a completed tube from glass. I had stayed Friday, Sat, & Sunday and by Monday finished a tube that not only worked above spec, was long lived, is still produced today 35 years later, with no modifications, has been widely copied by competitors, and it filled a critically new application at the time.

I had designed, drawn, machined, cleaned, assembled, brazed, glassed the metal, final sealed all parts, baked, processed, tested, packaged, & cabled; everything necessary in 1-weekend. Something that normally takes at least 4-weeks. With the proper equipment I’m able to move mountains.

-And thoroughly enjoy doing it! –

08.

Get help before you get your funding pulled!

A company founder came to me in despair indicating that they had been working with UC Berkeley, Argonne National Laboratory, TSA, … on a neutron source for multiple years without success and that congress was ready to pull the project funding.

The lawyer/ founder said he needed a fix immediately. I worked the weekend and into the nights, identified the problems, created a model with the corrected parts and geometry and even made plans to produce the units if it came to that.

I wrote the report and the founder came back saying their funding had been pulled.

I sent my report anyway to the national lab and they filed it with the project close.

09.

Side line

I have normally had a fulltime job and consulted on the side, with my employers permission, so I have always had to be cognizant and insure to give each company their fair due.

It has worked well having done it for so long, compartmentalizing businesses and knowing the history of vacuum tube technology, and what is in the public domain, so I insure that I don’t give away any “secrets”.

10.

10.

Sources I invented

Sources above are just a small portion of design I designed solely and were the basis of a company staying alive for so long. Spot sizes ranged from 6-micron dia. to 1-mm and 10kV to 130kV.

11.

6MeV Circular Accelerator

12.

12.

Military

A 70kV, 10-micron spot, portable was the beginning of the handheld portable dental market, of which I am on the patent for except that this needed to be kicked out the back of a transport plane on a pallet with a parachute, survive the ground impact, be able to be picked up and operated at full spec within less than 1 min.

Award Winning Designs

Simplis X-Ray

Satisfied Clients

Projects Completed

Awards Earned

Patents

Simplis X-Ray & Neutron Sources

If your x-ray, neutron, or high voltage and or vacuum source is not living up to your expectations on life, performance, stability or cost, please contact me. We can help in:

- Design

- Manufacturing

- Evaluation

- Trouble shooting

- Research

- Development

- Production

- Cost Reduction

- Marketing

- Consultations

Results Driven

Solving problems with x-ray and neutron source systems and applications, elegantly and simply. A company that works with and leverages international knowledge, skills, and material for the best solution for your particular application and need.

We help: Start-ups to Fortune 50 Companies, Government national labs, and critical projects

Simplis has a clear solution for you.

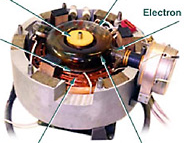

(Shown is a 50kV X-ray source I improved the production yield from less than a shaky 8% to over 90% and I could quickly improve even more but the customer said, “good enough”.)

Founder's Message

With over 45 years of highly practical and successful career work, I'm confident we can improve anything you can present. Our products have been nominated for two IR&D awards for Microlithography and Laminography. We've also received honorable mention in Test & Measurement World’s top 10 products of the decade and are committed to ongoing innovation with the utmost quality and efficacy.

Recommendations

in x-ray and neutron source vacuum-tube design for imaging, elemental identification, and gauging and other applications.

I recommend David to anyone in the high technology industry!

A few Areas of Expertise

With over 50 years of experience in x-ray and neutron development for imaging, elemental identification, gauging and in particular, source vacuum-tube design.

Design

Of continuously pumped vacuum chambers for test and processes Hundreds of sealed vacuum tube designs for reliability, longevity, beam flatness, High Power (Kilowatts). Mil Spec tube design for satellites (ultra-high reliability), tubes the size of a grain of rice. Completely new designs take longer due to needing to teach new processes or to design to the companies existing technologies/ skills.

Evaluation

Of sources, materials and processes for everything from life to robustness, to most-likely-yield, producibility, and weaknesses including neutron sources.

Bonding

Furnace brazing, vacuum and controlled-atmosphere, active brazing, vacuum grade. HIP, diffusion bonding, metallurgy, and welding, all types: TIG, MIG, Cold, Electron, Laser, Ion, Plasma, Explosive, Gas, Inertia/ Friction, Spot, Arc, Stick, Ultrasonic…

Electron/ Ion/ particle

Emitters; impregnated, scandate, enhanced emission, LaB6, Ce, materials for cathode emitters lasting 1 to 20+ year life with J’s of up to 18A/cm^2, balancing cost and performance. Direct emitters of W, Re, Pt… wound filaments, tape, and single crystal.

High Vacuum

From 10-15 torr, (extreme) down to 10-3 torr, (Paschen’s curve), for cutting-edge sputtering deposition techniques and to 760 mmHg, atmosphere. Getters; non-evaporative getters, (NEGs), flash, surface and bulk getters, to control vacuum levels from 10-3 torr to 10-15 torr.

Insulators:

Ceramics, Al2O3, BeO… oxides, glass blowing, Glass or ceramic-to-metal-seals, aluminosilicates, borosilicates ceramic assemblies. Specialized coatings for voltage and vacuum control. Oils, fluorocarbon/ perfluorocarbon fluids, gasses including SF6…

Coatings

Sputter, ion plating, CVD, PECVD, UVCVD, PVD, Laser or e-beam evaporative… Thin and thick coatings

High Voltage

From 500V to 2MeV and accelerated particle beams to > 10MeV. with nA leakage

Other Areas

Material selection

Solid modeling 3D & 2D drawing

Cleaning parts Chemical and furnace processing

Contact

World-Class Products

David Reynolds

Senior Scientist

Designer

R&D

Email & Phone

David_Reynolds@Simplis-X-Ray.com

(970) 689-6206